Statistical Process Control (SPC) - LogBook Monitor

Optimizing quality, reducing defects and inconsistencies in manufacturing is not always a simple task. We also know that understanding statistics is not an easy topic to explain however, LogBook Monitor utilizes color coded symbols to visualize Statistical Process Control (SPC).

Key Features

- Simplified real-time SPC monitoring.

- Visual indicators to see what is statistically in or out of control.

- Select the tests you want to statistically inspect.

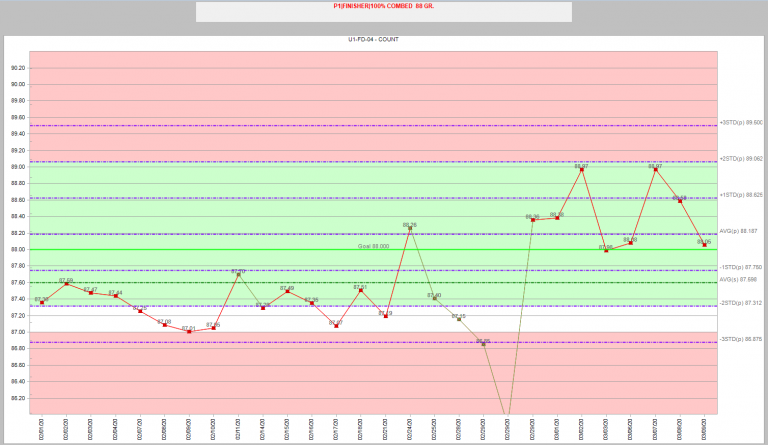

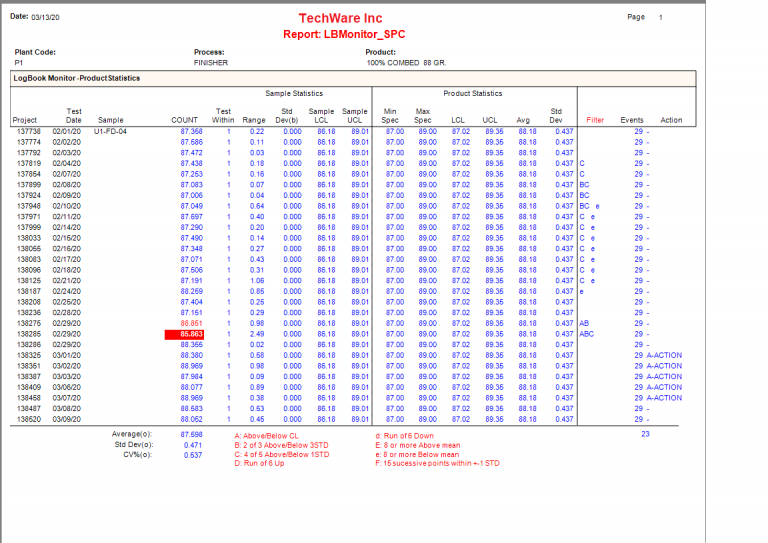

- Reports and charts based on 6 key statistical fundamentals.

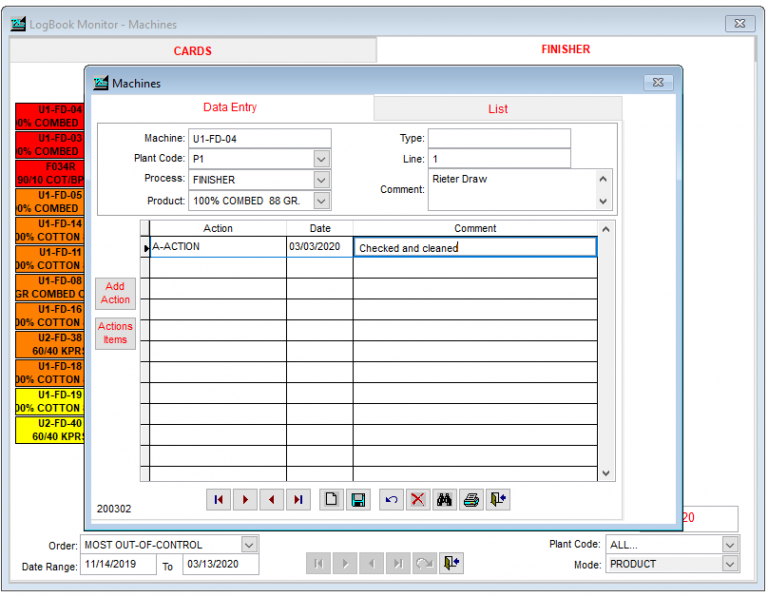

- Pin Point / Find Problems: Find quality problems and correct them before they become costly.

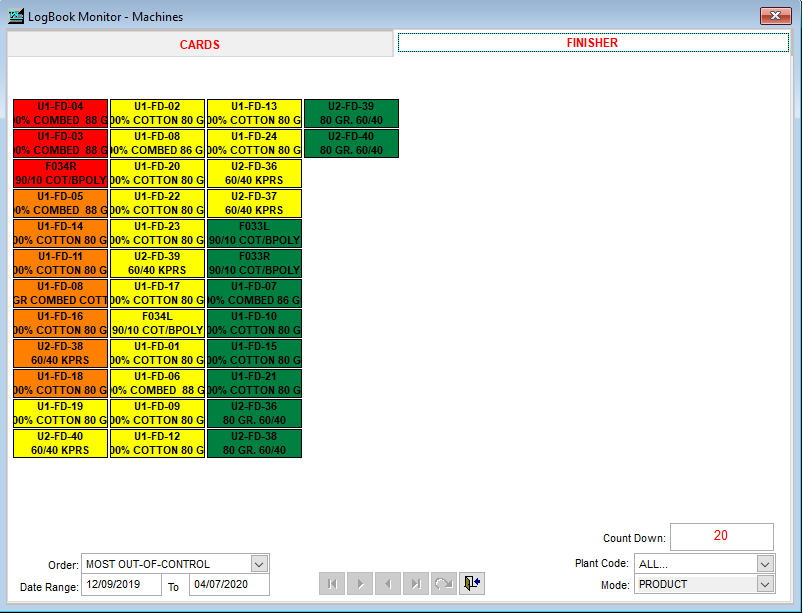

Real time SPC monitoring with LogBook Monitor

Visually see what machines and products are in or out of control

Most people know that red means stop, yellow means caution, and green means go. For this reason, LogBook Monitor was designed with these visual tools to help you know if a machine, process or sample requires attention. All of this happens in real time without re-entering data into another application.

SPC - "Out of Control" (OC) Conditions

- Condition “A” – if one or more points fall outside of the upper or lower control limits. Normally these limits are +- 3 standard deviations from the mean.

- Condition “B” – if two of three successive points fall beyond two standard deviations from the mean.

- Condition “C” – if four of five successive points fall beyond one standard deviations from the mean.

- Condition “D” – if there is a “run” of six or more point that are successively higher or lower.

- Condition “E” – if eight or more points fall on either side of the mean.

- Condition “F” – if 15 consecutive points fall 1 standard deviation on either side of the mean.